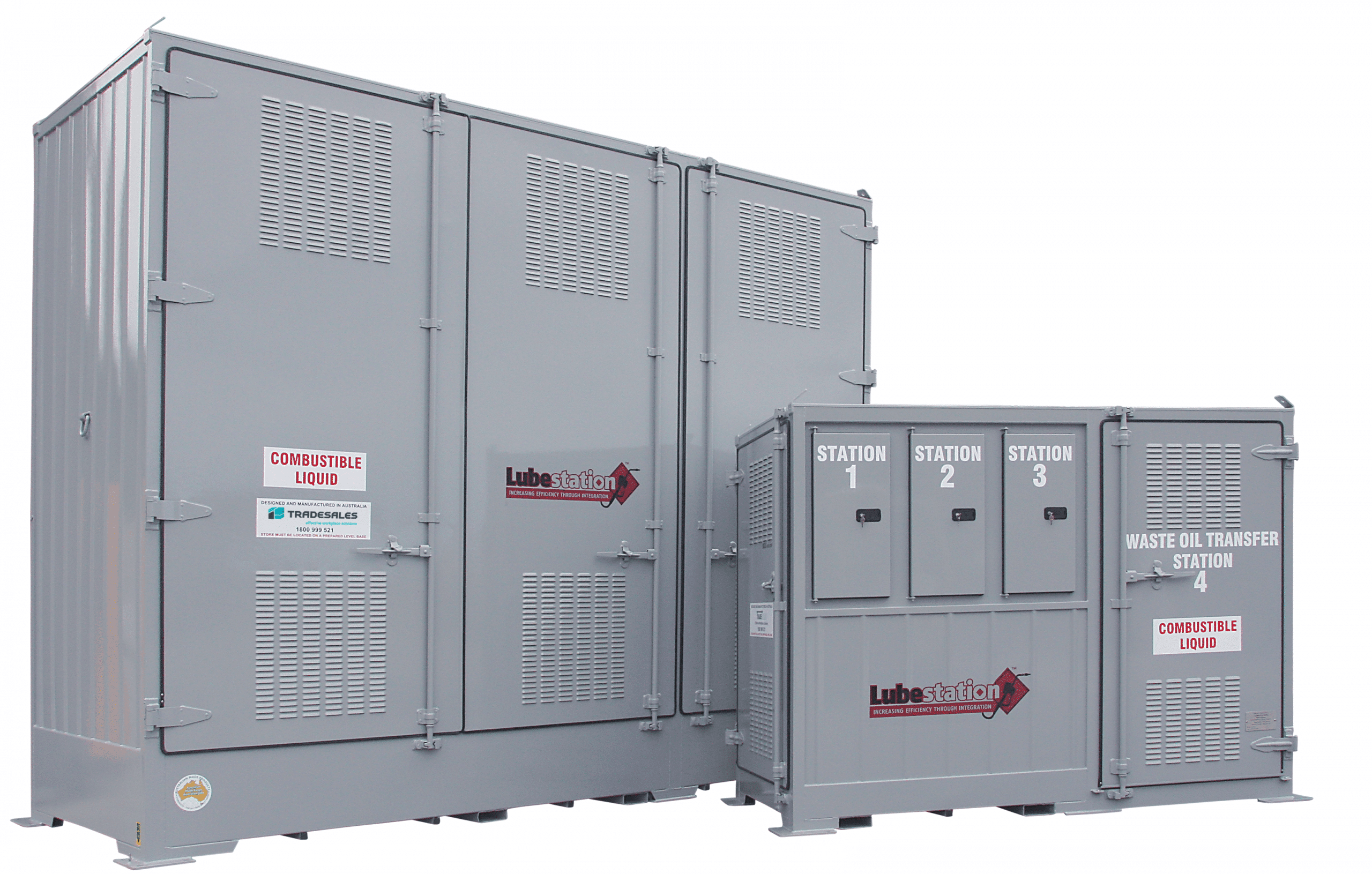

Description

LUBESTATION® modules are designed for fast, easy and contamination-free lubrication storage and dispensary.

Improving the lifespan and performance of machinery and ensuring the success of industrial operations.

LUBESTATION® Advantages:

- Durable, adaptable, and relocatable

- Simple to use and maintain

- Forklift Access doors for easy loading/unloading

- More efficient and cost-effective than permanent structures

- Maximises available space and storage capacity

- Minimal on-site preparation required

- Meets or exceeds the Australian standards

- Filtered and contamination-free lubrication

- Reduces spills, product wastage, and safety hazards